Websites Built for the Industry

Save up to 75% of your data entry time and increase your traffic by up to 4X

Boats Group offers the only marine website solution that seamlessly integrates with the industry’s most powerful inventory management system.

The #1 Website Platform for Boat Dealers and Brokers

Choose the option that meets your business needs and experience a web presence that you are proud of.

All The Benefits. No Set-Up Fee.

- Optimized for lead conversion

- Leading SEO value

- Responsive, mobile-first designs

- User-friendly navigation

- Access to OEM showrooms

- Dedicated hosting & support

- Social media integration

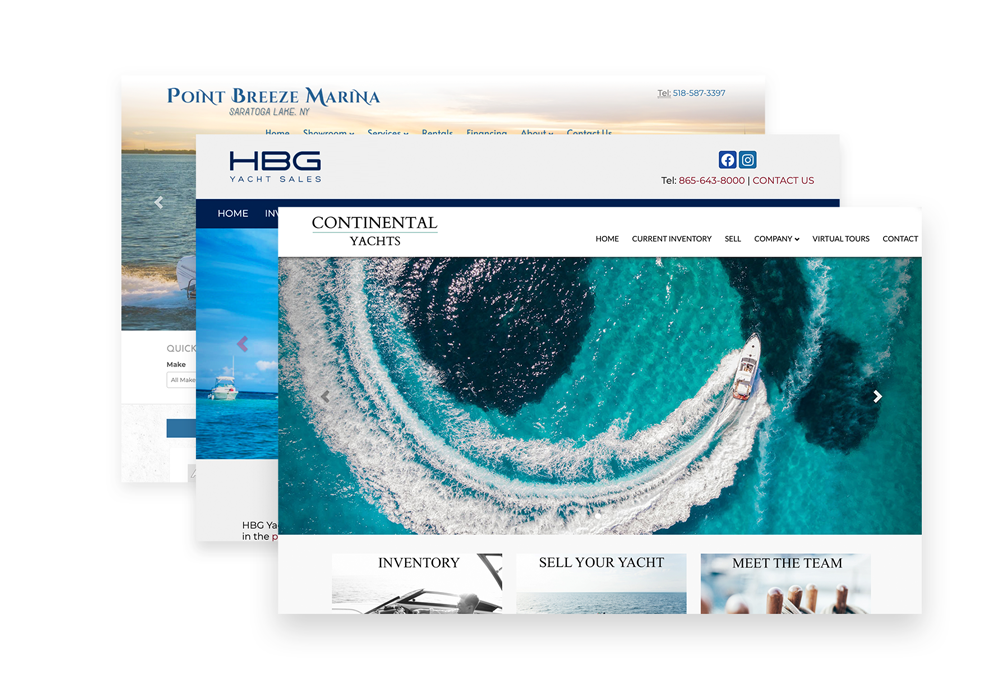

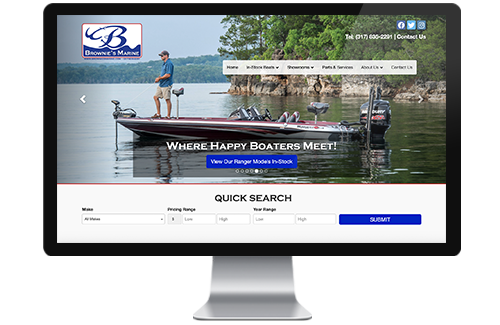

Our Portfolio

Krenzer Marine

Sodus Point, NY

NWYachtnet

Tacoma, WA

Brownies Marine

Fairland, IN

KB Marine Sales

Loxahatchee, FL

“Our site traffic has increased dramatically – not to mention it’s mobile-friendly. We have also noticed a longer interaction with those visiting our site – thus we have nothing but praises for the new site… Your team is truly a dealer partner, and we can’t say thanks enough!”